AI/ML and Model Operations

The AI Factory: Turning Raw Data Into Business Outcomes

Introduction

Think of AI as a factory.

Data is the raw material.

Infrastructure, pipelines, and models are the machinery.

Business outcomes are the finished goods rolling off the line.

Every company today is sitting on mountains of data. But for many mid-market firms, those warehouses of raw material are exactly that — warehouses. Piles of data, stored in silos, with no clear process to transform it into something useful. The “factory floor” is either empty or scattered with disconnected tools that don’t talk to each other.

Startups, by contrast, often begin with very little raw material. They don’t have decades of transactions, customer interactions, or sensor readings sitting in storage. But what they do build, from day one, is a small and efficient factory: streamlined pipelines, cloud-native infrastructure, and models designed to deliver a specific outcome. Their challenge is scale, not readiness.

This imbalance creates a paradox: the firms with the richest raw materials often lack the machinery, while the firms with working machinery often lack the material. The winners of the next decade will be those who solve both sides of the equation — efficient factories with access to abundant raw material.

To unlock that potential, companies need to understand what makes an AI factory run — how data, infrastructure, and models come together like assembly lines, quality controls, and machines on the factory floor.

What Makes an AI Factory Work

A successful factory doesn’t just stockpile raw materials — it organizes them, runs them through machines, and delivers consistent products at scale. An AI factory works the same way. Data, infrastructure, models, and governance each play a role on the production line, ensuring that the end result is more than a prototype — it’s a reliable outcome the business can trust.

Raw Material: Data Readiness

Press enter or click to view image in full size

Every product starts with raw material. In AI, that’s your data. If it’s messy, inconsistent, or locked away in silos, the line grinds to a halt. Clean, versioned, and accessible data is what keeps the machines running smoothly. Companies like Snowflake and Databricks have become the “supply yards” for data, giving firms modern warehouses instead of scattered silos. Tools like Fivetran and dbt help automate collection and transformation (ELT data integration pattern) so the raw material is usable on the line.

Added Context: ETL vs. ELT

For those less familiar with the terminology:

ETL (Extract, Transform, Load) was the traditional way companies managed data. You pulled data out of source systems, transformed it into a clean format, and only then loaded it into a warehouse.

ELT (Extract, Load, Transform) flips that model. Today, with cloud warehouses like Snowflake, BigQuery, or Databricks, firms load raw data first and then transform it inside the warehouse using tools like dbt.

Think of ETL as refining the raw material before putting it into storage, while ELT is storing it first, then refining it when you’re ready to use it.

Machinery: Infrastructure & Pipelines

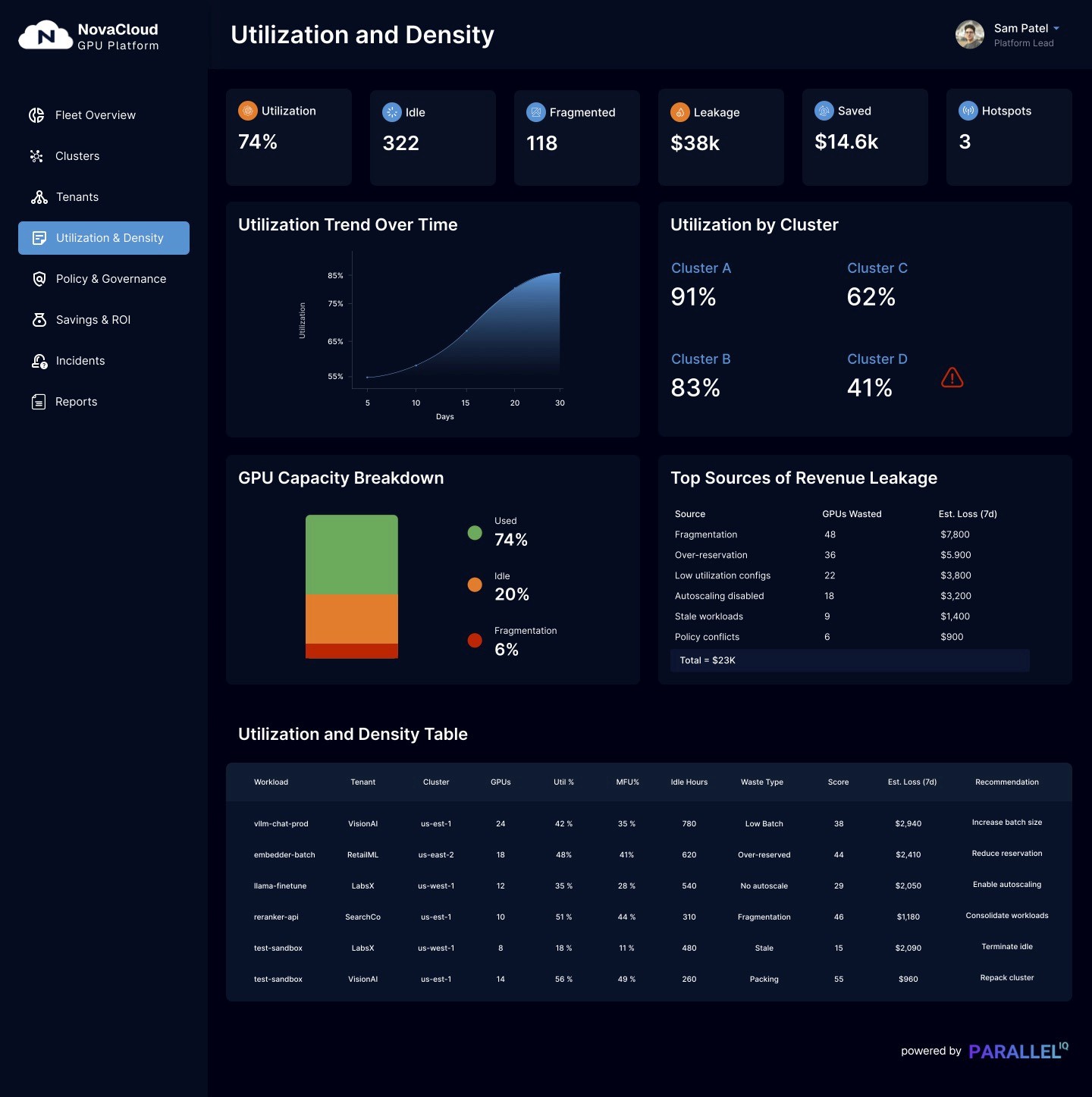

Press enter or click to view image in full size

Even the best raw material is useless without machines to process it. In an AI factory, those machines are your infrastructure and pipelines. They move data through ingestion, transformation, and model training — just as conveyor belts, presses, and welders move steel into shape. Platforms like AWS SageMaker, Google Vertex AI, and Kubeflow provide the industrial equipment, while Databricks MLflow helps orchestrate the line. The right setup ensures scalability and minimizes idle capacity — key for mid-market firms that can’t afford wasted GPU cycles.

Assembly Lines: Models & Training

Press enter or click to view image in full size

The heart of the factory is the assembly line. This is where raw material is shaped into something recognizable and valuable. In AI, it’s where models are trained, tuned, and retrained to improve accuracy over time.

Some companies choose outsourced assembly lines — fully built and always running. APIs from OpenAI, Anthropic (Claude), or Cohere let firms plug in their data and immediately start producing usable outputs, whether that’s text, search, or summaries.

Others prefer to source assembly kits and parts. Open-source communities like Hugging Face provide pre-trained models and libraries (Transformers, Diffusers), while Stability AI offers generative imagery pipelines such as Stable Diffusion. These are ready-made components that can be adapted and improved for custom use.

Finally, some firms invest in building custom lines of their own. Platforms like MosaicML (now part of Databricks) help companies design training pipelines optimized for efficiency and cost — essential for mid-market firms that want control and differentiation without starting from scratch.

But no matter which path you take — renting, borrowing, or building — assembly lines aren’t “set it and forget it.” They need iteration, feedback loops, and continuous improvement to keep producing high-quality goods that match business needs.

Quality Control: Observability & Governance

Press enter or click to view image in full size

No factory can ship goods without quality checks. In AI, this is observability and governance — detecting drift, enforcing compliance, and monitoring for bias or errors. Companies like Fiddler, Arize AI, and WhyLabs provide the equivalent of inspectors on the line, ensuring every product meets standards before leaving the factory. This step builds trust with regulators, customers, and internal teams — and prevents costly recalls later.

Finished Goods: Business Outcomes

Press enter or click to view image in full size

At the end of the line, the factory delivers products customers actually use. For AI, the finished goods are predictions, insights, automations, and decisions that directly affect revenue, efficiency, and competitiveness. You see this in products like Salesforce Einstein, ServiceNow AI, or vertical AI startups that package models directly into workflows for real estate, healthcare, or finance. These are the “shipped goods” that demonstrate AI’s value in the market.

👉 Together, these elements turn AI from a concept into a functioning factory — capable of taking raw data and consistently producing results the business can count on.

The Strategic Lesson

In AI, owning raw material isn’t enough. Data alone doesn’t create value; without the right machinery, it sits idle in warehouses and dashboards.

What separates experiments from real business outcomes is the ability to build and run a functioning factory — infrastructure, pipelines, models, and governance working together as one system. That’s what turns scattered data into revenue-driving insights and automation.

Mid-market firms already hold the gold. They have years of transactions, customer records, and operational data that startups would kill for. What they lack isn’t material — it’s the machinery to refine it into something usable. Building that factory is the step that moves them from “AI potential” to AI execution.

Closing Thought / Call-Forward

AI isn’t alchemy. It’s manufacturing. The winners won’t be those who hoard the most data, but those who align raw material, factory, and conveyor belt to deliver real results at scale.

This is the shift mid-market firms need to make: from warehouses of untapped data to factories that consistently produce measurable outcomes.

👉 In a future post, we’ll unpack what it takes to design this factory for efficiency and scale — so AI investments translate into sustained competitive advantage, not stalled experiments.

Where ParallelIQ Fits In

At ParallelIQ, we don’t sell the raw material and we don’t build the conveyor belts from scratch. Instead, we act as the factory designers and operators for mid-market firms.

We help you take the data you already own and make it production-ready.

We design the infrastructure and pipelines so the line runs efficiently, without wasted compute or idle GPUs.

We ensure your models and assembly lines are tuned to business goals, not just technical benchmarks.

And we embed observability and compliance so the “finished goods” meet both customer expectations and regulatory standards.

We help you take the data you already own and make it production-ready.

We design the infrastructure and pipelines so the line runs efficiently, without wasted compute or idle GPUs.

We ensure your models and assembly lines are tuned to business goals, not just technical benchmarks.

And we embed observability and compliance so the “finished goods” meet both customer expectations and regulatory standards.

The result: an AI factory that transforms your untapped data into real business outcomes — cutting waste, speeding time-to-value, and keeping you competitive with AI-native startups.

👉 Want to learn how we accelerate your AI execution?

[Schedule a call to discuss → here]